The basic production of a book:

Typesetting

1 First, the manuscript is converted into the desired font and point size. If the manuscript has not been completed on a computer, it must be typed into a computer by the type-setter. If it is already in electronic form, however, the typesetter simply has to make programming changes to convert the manuscript into the proper style. The result is generally a galley of the text. A galley form of manuscript consists of long pages of text in a single column. The galley includes the proper typeface, but the proper pagination still must be worked out.

2 Galleys are then proofread and edited for errors by the publisher. This stage is particularly important if the manuscript has been typeset (typed) from a hard copy of the text. If the manuscript was typeset from a computer disk, most of the errors should have already been corrected during a review of the manuscript. The single-column format of galleys facilitates the proofreading.

Pages and mechanical

Pages and mechanical

3 After galleys are thoroughly proofed and edited, pages (or lasers) are produced. An exact layout of typeset pages but usually printed on standard typing paper, pages are also reviewed for accuracy by the publisher. Some books skip the galley stage and proceed directly to pages. Once any necessary changes have been made, the typesetter then produces a mechanical of the typeset pages. Also called camera copy, the mechanical is printed on high-quality paper that is suitable for filming, the first stage in the printing process. The work of the typesetting vendor—if different from the publisher—is now done.

Filming

4 The typeset mechanical now goes to the printing and binding vendor. First, each text page, including line drawings, is photographed (or shot) using a large camera to produce page negatives. These negatives are the opposite of what will actually print. In other words, the text and photos will appear backward in negative form. Negatives are then checked to make sure there are no blemishes present. While printed words and line drawings are all one shade of black, photographs have many shades from palest gray to deepest black and must be filmed using a special process to maintain these shades. The process converts the shades into black and white dots—very light areas have many dots, while darker areas have fewer dots. The converted photographs are known as halftones. If the book will have more than one color of ink, a separate negative for each color is made. For color photos, for instance, four negatives are generally used: cyan, magenta, yellow, and black. For this reason, books with color will have negative overlays (one negative overlay for each color). Because of the added overlays, a book printed in more than one color involves additional preparation and cost.Stripping

5 The negatives are then taped or "stripped" into their proper place onto a large sheet called a goldenrod or a flat. Each flat holds 32 or 64 pages, and enough flats are used to equal the number of pages in the book. Strippers examine each finished flat on a lineup table to ensure that text and illustrations are properly lined up and in sequence. (The book pages are not lined up in consecutive order on the flat, and in fact some of the pages are placed upside down. Such placing is necessary because the finished paper version of each flat will be folded several times; once the flat is folded, the 32 or 64 pages will be in the proper order. This placement method is known as imposition.) To make this examination process easier, the lineup tables are equipped with a fluorescent light that shines up through the negatives, so it is easier for the stripper to read and align the text.Blueprints

6 To make sure the book is progressing properly, a proof of each flat is made by shining ultraviolet light through the negatives to expose their images onto a special light-sensitive paper. The resulting pages are called blueprints (or silverprints, bluelines, or dyluxes) because the paper and ink are blue or silver in appearance. The blueprints are then checked carefully by the publisher. If an editor or art director finds an error on a blueprint or decides to make a change, the page in question has to be rephotographed. The new negative will then be stripped onto the flat.Plate making

7 After final approval, each flat is photographed, with the negatives being exposed onto (or "burned" onto) a thin sheet of aluminum called a plate. The sections of the plates that contain text and illustrations are then treated with a chemical that attracts ink, thereby ensuring that the text and illustrations will print when on press.Printing

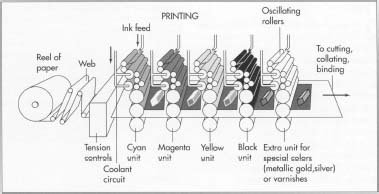

8 The plates are then sent to press. If printing in only one color, each plate will require only one pass through the press. If printing more than one color, an additional pass will be required for each color. For example, if two colors are used, the paper is fed through the press twice.There are three main printing processes used in book production: offset lithography, letter-press, and gravure. The process used depends less on quality differences than on economic factors such as availability of

Printing is often done on an offset lithography printing press, in which the paper is fed through rolls that are exposed to the proper ink. If colored ink is necessary, either for text or for photographs, each of the four major colors is offset onto its own set of rollers.machines, number of books being printed (the print run), and the speed of delivery. Presses are either sheet-fed (single sheets of paper are fed through) or web-fed (huge rolls of paper are unwound and run through).

Binding

9 After the sheets are printed and dry, they are delivered to the bindery. While many large printing companies have their own binderies, other smaller printers must send the printed sheets to a outside bindery. At the bindery, the flats are folded and collated into book signatures —properly folded 32- or 64-page sections—that are then bound in proper sequence. All of these functions are automated.10 Book binding also involves sewing the signatures together, gluing the spine, and inserting lining and trimming the edges. The amount and type of binding depends on the type of book (paperback or hardback) and its size. In the final step, the book is "cased in," or enclosed in a cover.

Applying these factors to my book's production:

How to format a document to send it to the printers:

- Allow for a 3mm bleed, in turn allowing imagery to run to the end of a spread. Crop marks are essential in order for the correct size of the book to be formed.

- Convert files to CMYK, giving an accurate perception of the colours in which are to be used.

- Covert all fonts to outlines, or package the file in order to ensure that all fonts are present.

- Insure all imagery is 300dpi (this was expressed within my books design.)

- PDF file

- Ensure template allows folding lines.

The spreads would firstly be cut down by that of an industrial sized guillotine.

Folding-A large machine called 'the folder' then sorts and folds the sheets. The machine starts by perforating the fold line, roller are then used in order to develop a neat fold. This is then how signatures are developed. The pages are then assembled, and placed upon a machine in which formulates the binding method, in this instance coptic.

Two machines are then used (one with the pages and the other with the cover) these two are then crossed over, glue is then used in order to attach the cover and spreads.

https://www.youtube.com/watch?v=mfcEFEaxaLs- Helpful video

Folding-A large machine called 'the folder' then sorts and folds the sheets. The machine starts by perforating the fold line, roller are then used in order to develop a neat fold. This is then how signatures are developed. The pages are then assembled, and placed upon a machine in which formulates the binding method, in this instance coptic.

Two machines are then used (one with the pages and the other with the cover) these two are then crossed over, glue is then used in order to attach the cover and spreads.

https://www.youtube.com/watch?v=mfcEFEaxaLs- Helpful video

No comments:

Post a Comment